The supply and control of heat within an oven with minimal loss is an integral process in optimizing the bread-baking process. Research over the years reports on measures to control heat, however, there is limited data on optimizing burner designs for efficient heat supply. Challenged with enhancing the functionality of a bread baking oven made locally, three different burner concepts (i.e., U, H and Rectangular shaped) were designed, fabricated and evaluated in a locally manufactured bread baking oven. The study investigated the three burner configurations to enhance the locally manufactured ovens' environmental sustainability, cost-effectiveness, and efficiency. The study also assessed each burner design concept's performance in relation to heat distribution, fuel consumption, and emissions through thorough experimentation and analysis. Thermocouples were used to determine the temperature differences within the oven and outside the oven walls to verify heat losses. The results showed that the concept burner design can be used to bake bread with good quality parameters like colour, texture and taste within efficient baking time. Computational Fluid Dynamic (CFD) analysis performed on the proposed burner design concepts in relation to heat flow show that continuous flow of heat was assured during baking. Also, simulation performed on the baking trays show an acceptable stress and strain levels as well as favorable factor of safety, indicating that the designs proposed is suitable for the purpose. Data analysis performed on the heat generated within the oven chamber considering the lower and upper trays for all the burners evaluated can be ranked in terms of percentage as RB > HB > UB (41.39% > 30.72% > 27.89%). Based on the study conducted, the authors can suggest the best design concept for heat generation in locally manufactured ovens should be rectangular-shaped.

| Published in | International Journal of Energy and Power Engineering (Volume 13, Issue 3) |

| DOI | 10.11648/j.ijepe.20241303.11 |

| Page(s) | 42-51 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2024. Published by Science Publishing Group |

Burner Design Concept, Bread-Baking Oven, Bread, Heat Transfer, Baking

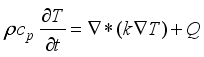

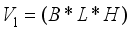

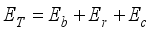

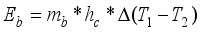

(1)

(1)  is the density of the oven material,

is the density of the oven material,  is the specific heat at constant pressure, T is the temperature, t is the time, k is the thermal conductivity,

is the specific heat at constant pressure, T is the temperature, t is the time, k is the thermal conductivity,  is the del operator and Q represents any heat generation or absorption. Steady-state characteristics are often taken into consideration for a baking oven. The time derivative term on the left side of the equation becomes zero in this situation.

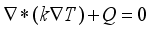

is the del operator and Q represents any heat generation or absorption. Steady-state characteristics are often taken into consideration for a baking oven. The time derivative term on the left side of the equation becomes zero in this situation.  (2)

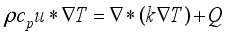

(2)  (3)

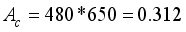

(3)  (4)

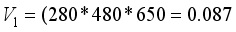

(4)  m2(5)

m2(5)  (6)

(6)  m3(7)

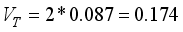

m3(7)  m3(8)

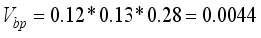

m3(8)  m3(9)

m3(9)  (10)

(10)  (11)

(11)  (12)

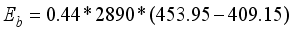

(12)  KJ(13)

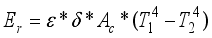

KJ(13)  (14)

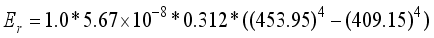

(14)  (15)

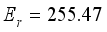

(15)  J/Sec(16)

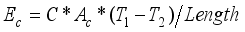

J/Sec(16)  (17)

(17) Burner type | Temperature °C | Difference Temp °C | ||||

|---|---|---|---|---|---|---|

T1-T4 | T1-T4 | D1 | D2 | |||

H | 45 | 55 | 70 | 80 | 10 | 10 |

U | 47 | 67 | 63 | 83 | 20 | 20 |

RB | 35 | 60 | 56 | 66 | 25 | 10 |

Comparison | P | P<0.05 |

|---|---|---|

P1 Vs P2 | <0.001 | Yes |

P1 Vs P3 | <0.001 | Yes |

P1 Vs P4 | <0.001 | Yes |

P4 Vs P2 | 0.043 | Yes |

P4 Vs P3 | 0.473 | No |

P3 Vs P2 | 0.639 | No |

Comparison | P | P<0.05 |

|---|---|---|

P2 Vs P1 | <0.001 | Yes |

P2 Vs P4 | 0.141 | No |

P2 Vs P3 | 0.784 | No significant difference |

P3 Vs P1 | <0.001 | Yes |

P3 Vs P4 | 0.626 | No significant difference |

P4 Vs P1 | <0.001 | Yes |

3D | Three-Dimensional |

ANOVA | Analysis of Variance |

CFD | Computational Fluid Dynamic |

HB | H-shaped Burner |

RB | Rectangular Burner |

UB | U-shaped Burner |

| [1] | Afolabi Tunde Morakinyo, (2017), “Development and Optimization of Operational Parameters of a Gas-Fired Baking Oven”, Leonardo Journal of Sciences, ISSN 1583-0233, pp. 45-64. |

| [2] | Akinnuli B. O and Basil Olufem, (2019), “Fabrication and Performance Evaluation of Designed Multipurpose Domestic Gas Baking Oven” East African Scholars Journal of Engineering and Computer Sciences, Vol. 2, ISSN 2617-4480 (Print) | ISSN 2663-0346 (Online). |

| [3] | Edgar Ramirez-Laboreo, et al (2016),” Dynamic Heat and Mass Transfer Model of an Electric Oven for Energy Analysis”, Applied Thermal Engineering, Volume 93, Pages 683-691. |

| [4] | Genitha I. et al. (2014), “Design, Fabrication and Performance Evaluation of Domestic Gas Oven”, IOSR Journal of Engineering (IOSRJEN), Vol. 04, Issue 05(May. 2014), ||V5|| pp. 35-38. |

| [5] | J. P. Abraham and E. M. Sparrow, (2002), “Heat Transfer Coefficients and other Performance Parameters for variously positioned and supported Thermal Loads in Ovens with/without water-filled or empty blockages”, International Journal of Heat and Mass Transfer, Volume 45, Issue 17, Pages 3597-3607. |

| [6] | Keneingunuo Pfuse, (2022), “A Brief Study of Baking Business in Kohima”, Department of Commerce Kohima College Kohima 797001. |

| [7] | M. Marcotte et al. (2007), “Heat and Mass Transfer during Baking” Agriculture and Agri-Food Canada, St. Hyacinthe, Quebec, Canada, WIT Transactions on State of the Art in Science and Engineering, Vol 13. |

| [8] | Mirades et al. (2004), “Characterization and CFD Modelling of air Temperature and Velocity Profiles in an Industrial Biscuit Baking Tunnel Oven”, Food Research International 37(10): 1031-1039. |

| [9] | Ploteau et al. (2015), “Experimental Investigation of French Bread Baking Under Conventional Conditions or Short Infrared Emitters”, Applied Thermal Engineering, 75: 461-467. |

| [10] | R. Mythili et al, (2020), “Preparation and Baking the Products In the Oven”, 9th-Food processing.indb, (9th_Food_processing.pdf (rajshaladarpan.nic.in). |

| [11] | Rosita Junus et al. (1994), “The Effects of Design Factors on Emissions from Natural Gas Cooktop Burners”, International Journal of Environmental Studies, 45: 101–121. |

| [12] | Sawey, D. A., & Orge, R. F. (2022), “Performance of a Cylindrical Dryer-Oven Utilizing Otherwise-wasted Heat from Carbonizer’s Chimney”, International Journal of Ambient Energy, pp. 1-23. |

| [13] | Suvit Tia et al. (2007), “Effect of Burner Type on Thermal Efficiency and Emission of LPG Cookstoves”, Research and Development Journal Volume 18 No.1. |

| [14] | Wenxue Gao, et al. (2023), “Comprehensive Review on Thermal Performance Enhancement of Domestic Gas Stoves”, ACS Omega 2023, 8, 26663−26684. |

| [15] | Yung-Chang Ko and Ta-Hui Lin (2003), “Emissions and Efficiency of a Domestic Gas Stove Burning Natural Gases with Various Compositions”, Energy Conversion and Management, Volume 44, Issue 19, Pages 3001-3014. |

| [16] | Z. Khatir et al. (2012), “Computational Fluid Dynamics (CFD) Investigation of Air Flow and Temperature Distribution in A Small-Scale Bread-Baking Oven”, Applied Energy, Volume 89, Issue 1, Pages 89-96. |

APA Style

Kofi, S. D., Kwabena, O. G., Addai, B., Anto, M. (2024). Comparative Analysis of Different Burner Concepts in a Locally Manufactured Bread-Baking Oven. International Journal of Energy and Power Engineering, 13(3), 42-51. https://doi.org/10.11648/j.ijepe.20241303.11

ACS Style

Kofi, S. D.; Kwabena, O. G.; Addai, B.; Anto, M. Comparative Analysis of Different Burner Concepts in a Locally Manufactured Bread-Baking Oven. Int. J. Energy Power Eng. 2024, 13(3), 42-51. doi: 10.11648/j.ijepe.20241303.11

AMA Style

Kofi SD, Kwabena OG, Addai B, Anto M. Comparative Analysis of Different Burner Concepts in a Locally Manufactured Bread-Baking Oven. Int J Energy Power Eng. 2024;13(3):42-51. doi: 10.11648/j.ijepe.20241303.11

@article{10.11648/j.ijepe.20241303.11,

author = {Samuel Darko Kofi and Offeh Gyimah Kwabena and Bismark Addai and Michael Anto},

title = {Comparative Analysis of Different Burner Concepts in a Locally Manufactured Bread-Baking Oven

},

journal = {International Journal of Energy and Power Engineering},

volume = {13},

number = {3},

pages = {42-51},

doi = {10.11648/j.ijepe.20241303.11},

url = {https://doi.org/10.11648/j.ijepe.20241303.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ijepe.20241303.11},

abstract = {The supply and control of heat within an oven with minimal loss is an integral process in optimizing the bread-baking process. Research over the years reports on measures to control heat, however, there is limited data on optimizing burner designs for efficient heat supply. Challenged with enhancing the functionality of a bread baking oven made locally, three different burner concepts (i.e., U, H and Rectangular shaped) were designed, fabricated and evaluated in a locally manufactured bread baking oven. The study investigated the three burner configurations to enhance the locally manufactured ovens' environmental sustainability, cost-effectiveness, and efficiency. The study also assessed each burner design concept's performance in relation to heat distribution, fuel consumption, and emissions through thorough experimentation and analysis. Thermocouples were used to determine the temperature differences within the oven and outside the oven walls to verify heat losses. The results showed that the concept burner design can be used to bake bread with good quality parameters like colour, texture and taste within efficient baking time. Computational Fluid Dynamic (CFD) analysis performed on the proposed burner design concepts in relation to heat flow show that continuous flow of heat was assured during baking. Also, simulation performed on the baking trays show an acceptable stress and strain levels as well as favorable factor of safety, indicating that the designs proposed is suitable for the purpose. Data analysis performed on the heat generated within the oven chamber considering the lower and upper trays for all the burners evaluated can be ranked in terms of percentage as RB > HB > UB (41.39% > 30.72% > 27.89%). Based on the study conducted, the authors can suggest the best design concept for heat generation in locally manufactured ovens should be rectangular-shaped.

},

year = {2024}

}

TY - JOUR T1 - Comparative Analysis of Different Burner Concepts in a Locally Manufactured Bread-Baking Oven AU - Samuel Darko Kofi AU - Offeh Gyimah Kwabena AU - Bismark Addai AU - Michael Anto Y1 - 2024/05/30 PY - 2024 N1 - https://doi.org/10.11648/j.ijepe.20241303.11 DO - 10.11648/j.ijepe.20241303.11 T2 - International Journal of Energy and Power Engineering JF - International Journal of Energy and Power Engineering JO - International Journal of Energy and Power Engineering SP - 42 EP - 51 PB - Science Publishing Group SN - 2326-960X UR - https://doi.org/10.11648/j.ijepe.20241303.11 AB - The supply and control of heat within an oven with minimal loss is an integral process in optimizing the bread-baking process. Research over the years reports on measures to control heat, however, there is limited data on optimizing burner designs for efficient heat supply. Challenged with enhancing the functionality of a bread baking oven made locally, three different burner concepts (i.e., U, H and Rectangular shaped) were designed, fabricated and evaluated in a locally manufactured bread baking oven. The study investigated the three burner configurations to enhance the locally manufactured ovens' environmental sustainability, cost-effectiveness, and efficiency. The study also assessed each burner design concept's performance in relation to heat distribution, fuel consumption, and emissions through thorough experimentation and analysis. Thermocouples were used to determine the temperature differences within the oven and outside the oven walls to verify heat losses. The results showed that the concept burner design can be used to bake bread with good quality parameters like colour, texture and taste within efficient baking time. Computational Fluid Dynamic (CFD) analysis performed on the proposed burner design concepts in relation to heat flow show that continuous flow of heat was assured during baking. Also, simulation performed on the baking trays show an acceptable stress and strain levels as well as favorable factor of safety, indicating that the designs proposed is suitable for the purpose. Data analysis performed on the heat generated within the oven chamber considering the lower and upper trays for all the burners evaluated can be ranked in terms of percentage as RB > HB > UB (41.39% > 30.72% > 27.89%). Based on the study conducted, the authors can suggest the best design concept for heat generation in locally manufactured ovens should be rectangular-shaped. VL - 13 IS - 3 ER -