In this study, the authors investigated the tractive resistance forces that arise during the operation of a potato planting machine equipped with a disc-type working body. This working organ simultaneously performs two essential functions in the planting process: it opens a furrow in the soil for placing potato seeds and forms a ridge that covers and protects the seeds after planting. The analysis was carried out by taking into account a number of interrelated factors that directly influence the magnitude of draft resistance. These include the total mass of the potato planting machine, the physical and mechanical characteristics of the soil (such as density, hardness, and moisture content), as well as the geometrical parameters of the cultivated soil cross-section. The configuration and structural design of the working part, the machine’s coverage width, the planting depth, and the forward speed of operation were also considered as significant variables. The findings demonstrate that the draft resistance of the potato planter is not determined by a single factor but results from the combined effects of machine design, soil conditions, and operational parameters. In particular, the resistance force depends heavily on the machine’s mass, the width of coverage, and the performance of its various working components, including the furrow opener, the seeding mechanism, and other auxiliary parts that contribute to the planting process. Moreover, planting depth and soil texture strongly influence the overall resistance encountered during field operation. Based on the calculations and analysis presented, it was established that when the machine operates at forward speeds ranging from 4 to 6 km/h, the tractive resistance values vary between 1.702 kN and 2.823 kN. These results provide important insights into the design optimization of potato planting machines and offer practical guidance for selecting tractors of suitable power, improving energy efficiency, and ensuring reliable field performance under varying soil and load conditions.

| Published in | American Journal of Mechanics and Applications (Volume 12, Issue 4) |

| DOI | 10.11648/j.ajma.20251204.11 |

| Page(s) | 75-80 |

| Creative Commons |

This is an Open Access article, distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution and reproduction in any medium or format, provided the original work is properly cited. |

| Copyright |

Copyright © The Author(s), 2025. Published by Science Publishing Group |

Mutual Inclination Angle, Intersection Angle, Furrow Width, Tractive Resistance, Furrow Bottom, Paired Discs, Rippers, Furrow Opener, Power, Plowing Depth, Soil Cross-section, Working Parts

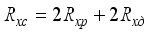

(1)

(1)  - groove opener's draft resistance, N;

- groove opener's draft resistance, N;  -disk drag resistance, N;

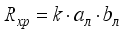

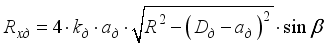

-disk drag resistance, N;  (2)

(2)  (3)

(3)  - specific resistance of soil, kN/M2 (15.... 25)

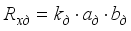

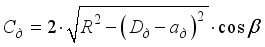

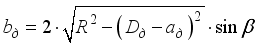

- specific resistance of soil, kN/M2 (15.... 25)  – disk-formed ridge width, m.

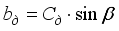

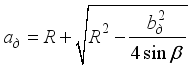

– disk-formed ridge width, m.  (4)

(4)  (5)

(5)  (6)

(6)  (7)

(7)  (8)

(8) Groove Opener's Draft Resistance | |

Disk Drag Resistance | |

Specific Resistance of Soil | |

Disk -Formed Ridge Width |

| [1] | FreshPlaza. FAOSTAT 2024: Global potato production rises despite shrinking harvested area. Available from: |

| [2] | Bayboboyev, N. G., Makhmudov, K. S., Mamadaliyev, A. M., & Yuldashev, O. T. (2025, July). Study of the drive for rotation transmission to the shaft of potato planter landers. In AIP Conference Proceedings (Vol. 3256, No. 1, p. 060043). AIP Publishing LLC. |

| [3] | Bayboboyev, N. G., Mamadaliev, A. M. U., & Yuldashev, O. T. (2024). Analysis of the Design of Seed Planter Machine Meters. Mechanics and Technology, 2(15), 65–70. |

| [4] | Duskulov, A. A., Makhmudov, K. S., & Yuldashev, O. T. (2024). Stubble potato planter for sustainable farming. In BIO Web of Conferences (Vol. 105, p. 01010). EDP Sciences. |

| [5] | Duskulov, A. A., Sultonkhodzhaevich, M. ? Mamadaliev, A. M., & Yuldashev, O. T. (2023). Improvement of the Combined Potato Planting Machine. Mechanics and Technology, (3(6) Special Issue), 39–44. |

| [6] | Patent, “Metering Device of a Potato Planting Machine,” No. 2830906, 2024. |

| [7] | Goryachkin, V. P. Collected Works. Vols. 1–3. Moscow: Kolos, 1965. |

| [8] | Zimmerman, M. Z. Working Tools of Soil-Cultivating Machines. Moscow: Mashinostroenie, 1978. p. 295. |

| [9] | Sharma, D. N. and Mukes, S. 2010. Farm Machinery Design: Principles and Problems. Second Revised and Enlarged Edition. |

| [10] | Dubey, A. K. 2003. Teaching material for training on computer aided design and design methodology for agricultural machinery. National Agricultural Technology Project on Team of Excellence on Agricultural Machinery Design and Development. CIAE, Bhopal. p 79. |

| [11] | Atul, K. and Satyendra, J. 2011. Modeling and performance evaluation of tractor drawn improved till plant machine under vertisol. Agricultural Engineering International: The CIGR Journal. Manuscript No. 1260. Vol. 13. Issue 2, June, 2011. |

| [12] | Kurtz, G., Thompson, L. and Clwar, P. 1984. Design of Agricultural Machinery. John Willey and Sons, Singapore, pp 245 - 255. |

| [13] | Yuldashev, O. (2021). SCIENTIFIC AND TECHNOLOGICAL BASIS OF POTATO DEVELOPMENT. Galaxy International Interdisciplinary Research Journal. |

| [14] | Amantayev, M., Gaifullin, G., Kravchenko, R., Kushnir, V., & Nurushev, S. (2018). Investigation of the furrow formation by the disc tillage tools. Bulgarian Journal of Agricultural Science, 24(4), 704-709. |

| [15] | Kalimullin, M. N., Khaliullin, D. T., Gaifullin, I. Kh., & Khamitov, R. R. (2022). Justification and Determination of the Parameters of a Potato Planter Furrow Opener. Technical Sciences. Bulletin of Kazan State Agrarian University, No. 3(67). |

APA Style

Tashpulatovich, Y. O. (2025). Justification of the Track Resistance of the Working Bodies of the Potato Planting Machine. American Journal of Mechanics and Applications, 12(4), 75-80. https://doi.org/10.11648/j.ajma.20251204.11

ACS Style

Tashpulatovich, Y. O. Justification of the Track Resistance of the Working Bodies of the Potato Planting Machine. Am. J. Mech. Appl. 2025, 12(4), 75-80. doi: 10.11648/j.ajma.20251204.11

AMA Style

Tashpulatovich YO. Justification of the Track Resistance of the Working Bodies of the Potato Planting Machine. Am J Mech Appl. 2025;12(4):75-80. doi: 10.11648/j.ajma.20251204.11

@article{10.11648/j.ajma.20251204.11,

author = {Yuldashev Odiljon Tashpulatovich},

title = {Justification of the Track Resistance of the Working Bodies of the Potato Planting Machine

},

journal = {American Journal of Mechanics and Applications},

volume = {12},

number = {4},

pages = {75-80},

doi = {10.11648/j.ajma.20251204.11},

url = {https://doi.org/10.11648/j.ajma.20251204.11},

eprint = {https://article.sciencepublishinggroup.com/pdf/10.11648.j.ajma.20251204.11},

abstract = {In this study, the authors investigated the tractive resistance forces that arise during the operation of a potato planting machine equipped with a disc-type working body. This working organ simultaneously performs two essential functions in the planting process: it opens a furrow in the soil for placing potato seeds and forms a ridge that covers and protects the seeds after planting. The analysis was carried out by taking into account a number of interrelated factors that directly influence the magnitude of draft resistance. These include the total mass of the potato planting machine, the physical and mechanical characteristics of the soil (such as density, hardness, and moisture content), as well as the geometrical parameters of the cultivated soil cross-section. The configuration and structural design of the working part, the machine’s coverage width, the planting depth, and the forward speed of operation were also considered as significant variables. The findings demonstrate that the draft resistance of the potato planter is not determined by a single factor but results from the combined effects of machine design, soil conditions, and operational parameters. In particular, the resistance force depends heavily on the machine’s mass, the width of coverage, and the performance of its various working components, including the furrow opener, the seeding mechanism, and other auxiliary parts that contribute to the planting process. Moreover, planting depth and soil texture strongly influence the overall resistance encountered during field operation. Based on the calculations and analysis presented, it was established that when the machine operates at forward speeds ranging from 4 to 6 km/h, the tractive resistance values vary between 1.702 kN and 2.823 kN. These results provide important insights into the design optimization of potato planting machines and offer practical guidance for selecting tractors of suitable power, improving energy efficiency, and ensuring reliable field performance under varying soil and load conditions.

},

year = {2025}

}

TY - JOUR T1 - Justification of the Track Resistance of the Working Bodies of the Potato Planting Machine AU - Yuldashev Odiljon Tashpulatovich Y1 - 2025/10/10 PY - 2025 N1 - https://doi.org/10.11648/j.ajma.20251204.11 DO - 10.11648/j.ajma.20251204.11 T2 - American Journal of Mechanics and Applications JF - American Journal of Mechanics and Applications JO - American Journal of Mechanics and Applications SP - 75 EP - 80 PB - Science Publishing Group SN - 2376-6131 UR - https://doi.org/10.11648/j.ajma.20251204.11 AB - In this study, the authors investigated the tractive resistance forces that arise during the operation of a potato planting machine equipped with a disc-type working body. This working organ simultaneously performs two essential functions in the planting process: it opens a furrow in the soil for placing potato seeds and forms a ridge that covers and protects the seeds after planting. The analysis was carried out by taking into account a number of interrelated factors that directly influence the magnitude of draft resistance. These include the total mass of the potato planting machine, the physical and mechanical characteristics of the soil (such as density, hardness, and moisture content), as well as the geometrical parameters of the cultivated soil cross-section. The configuration and structural design of the working part, the machine’s coverage width, the planting depth, and the forward speed of operation were also considered as significant variables. The findings demonstrate that the draft resistance of the potato planter is not determined by a single factor but results from the combined effects of machine design, soil conditions, and operational parameters. In particular, the resistance force depends heavily on the machine’s mass, the width of coverage, and the performance of its various working components, including the furrow opener, the seeding mechanism, and other auxiliary parts that contribute to the planting process. Moreover, planting depth and soil texture strongly influence the overall resistance encountered during field operation. Based on the calculations and analysis presented, it was established that when the machine operates at forward speeds ranging from 4 to 6 km/h, the tractive resistance values vary between 1.702 kN and 2.823 kN. These results provide important insights into the design optimization of potato planting machines and offer practical guidance for selecting tractors of suitable power, improving energy efficiency, and ensuring reliable field performance under varying soil and load conditions. VL - 12 IS - 4 ER -